Principle

Importance of filtration in microbiology history

In the early days of microbiology, liquids were filtered through hollow, unglazed porcelain candles. The long, convoluted channels through the filter’s walls absorbed the germs. In the 1890s, as interest in viruses grew, filters were utilized extensively in microbiology. Since then, filters have been used to separate viruses from other microbes and to sterilize bacterial medium after using them for bacteriological research and capturing airborne germs.

Charles Chamberland, a Pasteur collaborator, was one of the early innovators of filter technology. An early study on viruses benefited from his porcelain filter. Another trailblazer was Julius Petri, who created the Petri dish and a sand filter to remove microorganisms from the air.

Define filtration sterilization

The sterilization process by filtration method in laboratories is interesting. It’s the only approach that employs violence to separate rather than to kill. The passage of larger particles is blocked or filtered out by a pore in a filter as a liquid or gas travels through it. Pore diameters affect how much material can be filtered; smaller pores can filter more material, but doing so requires more force. Smaller proteins can still pass through pores that can be as small as 0.1 um, which are too large for viruses to pass through. To inhibit viruses, proteins, and some poisons, there are even incredibly tiny filters called nano-filters.

How does the filter work?

When a particle is less than the pore size, a filter physically traps it; when

the particle is larger, a filter retains it due to electrostatic attraction. In addition to porosity, the following other variables also affect filtration effectiveness:

- The fluid is the filtrad’s composition.

- The organisms’ electric charge.

- The filter’s electric charge.

Liquids can be filtered either by pulling them through cellulose acetate or cellulose nitrate membranes under vacuum (i.e., applying negative pressure to the filter paper) or by pushing them through the filter paper (i.e., applying positive pressure above the fluid).

High-efficiency particulate air (HEPA) filters are used to filter the air in isolation rooms, operating theatres, and biological safety cabinets. These filters are made to eliminate organisms larger than 0.3 m.

Depth filter

A depth filter is a fibrous sheet or mat made of paper or borosilicate (glass) fibers that have been randomly arranged and overlapped. In the structure’s network of fibers, the depth filter captures particles.

Uses:

- In industrial procedures, the air is sterilized through filters.

- Simple depth filters are used in forced-air heating and cooling systems in homes to capture dust, spores, and allergies.

- Application in biosafety settings, such as biosafety cabinets. High-efficiency particulate air (HEPA) filters, a form of depth filter, are found in biological safety cabinets.

HEPA filter

A typical HEPA filter is made of a single sheet of borosilicate glass fiber that has been coated with water-repellent glue. The filter is set inside a strong, supporting frame and is pleated to improve the filter’s overall surface area. HEPA filters exist in a variety of sizes and forms, ranging from a few square centimeters for vacuum cleaners to several square meters for biological containment hoods and room air systems.

Construction of “clean rooms” and isolation rooms for quarantine, as well as specialized diagnostic/research laboratories, is made possible by the control of airborne particulate contaminants provided by HEPA filters. HEPA filters typically remove 0.3-micron test particles from the airstream with an efficiency of at least 99.97%, including the majority of microorganisms.

Membrane filter technique

The most popular type of filter used for liquid sterilization in a microbiology lab is a membrane filter. High tensile strength polymers like polysulfone, cellulose acetate, and cellulose nitrate make up membrane filters. Membrane filters are made of circular membranes that are about 150 mm thick and have millions of microscopic pores that are of the same size. During the polymerization process, the size of the pores is modified based on the requirements.

The most often used membrane filter has pore sizes between 0.22 um and 0.45 um. To remove bigger particles that could clog the membrane filter, depth filters constructed of glass fibers are frequently used before the membranes. After being forced or pulled through the filter, the solution is collected in pre-sterilized containers.

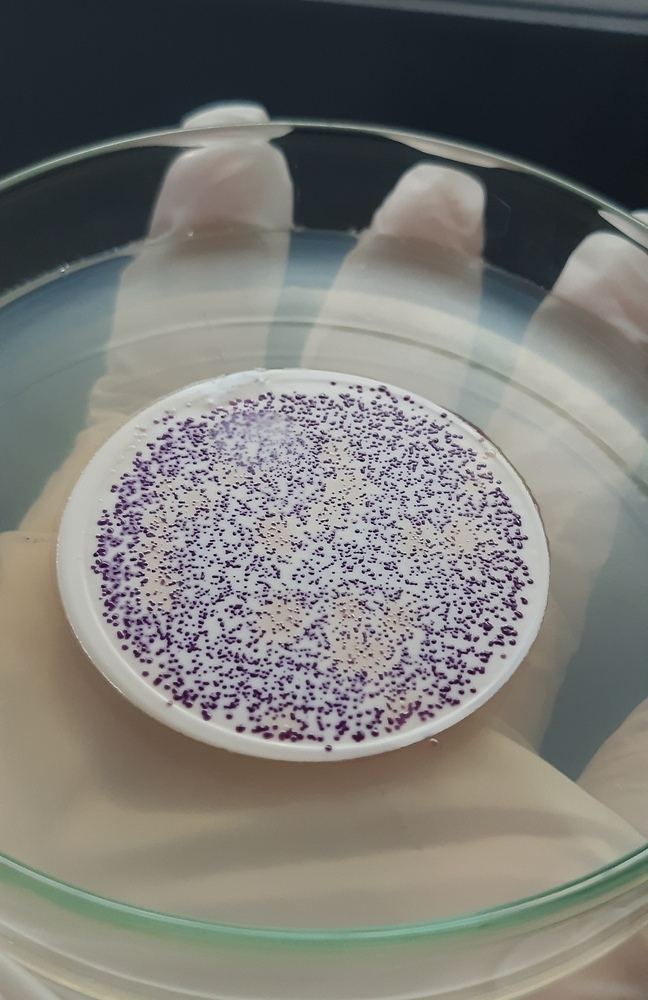

The procedure of membrane filter technique

- Gather the sample and do any required dilutions.

- Make the proper dilution in sterile water. And mix it well

- Forceps should be flamed before removing the membrane from the sterile container.

- The funnel assembly should contain the membrane filter.

- Fill the funnel with 100 ml of the

- Activate the vacuum and let the sample entirely pass through the filter.

- Use sterile buffered water to rinse the funnel. Set the vacuum to full pressure and let the liquid pass entirely through the filter.

- Remove the membrane filter from the funnel using flaming forceps.

- Put the membrane filter in the Petri dish that has been prepared.

- Incubate for the right amount of time and at the right temperature.

- Report the results after counting and verifying the colonies which indicate bacterial growth.

Results and interpretation

Colonies formed on the filter will count according to the formula mentioned below

CFU/100ml= colonies obtained x dilution factor/volume of specimen used.

Uses of filter membrane

- Membrane filters are widely employed in the business and in laboratories to sterilize materials that could be harmed by heat treatment. These elements include medicinal items including medications, hormones, sera, and vitamins, as well as dietary supplements from popular culture.

- Suitable and efficient methods for air quality, drinking water, etc.

- used for monitoring germs in the food and beverage, electronics, cosmetics, and pharmaceutical industries.

- Allows for the removal of bacteriostatic or bactericidal agents that cannot be removed using the pour plate, spread plate, or MPN techniques.

- By choosing a membrane filter with the right porosity, it is possible to allow the interested organism to pass through it selectively. These procedures are used in the pharmaceutical sector to permit the passage of a specific virus strain during vaccine preparation.

the advantages and disadvantages of the filtration technique.

Advantages

- Except for those with the smallest pore diameters, reasonably affordable

- Filters do not frequently clog.

- suitable for liquids that react poorly to heat because filters don’t use heat

- They can filter enormous amounts of fluid rather quickly.

Disadvantages

- This method can only sterilize liquids and gases.

- The cost of replacing filters, particularly nano filters, is high.

- The effectiveness of this process is impacted by the inherent limitations of the materials employed in filters, such as the breaking of glass filters, rupture of membrane filters, and absorption of the filtrate by Sietz filters.

- Clogging could happen.

References:

https://tuttnauer.com/blog/liquids-sterilization-by-filtration

http://microbiologyon-line.blogspot.com/2009/08/filtration.html

https://microbeonline.com/filtration-sterilization-types-mechanism-and-uses/