What is a centrifuge machine?

A centrifuge is a laboratory device used to separate sample components based on their densities. It works by rapidly spinning the sample, causing the heavier components to flow to the outside of the tube or container while the lighter components remain closer to the center. Sedimentation is a technique that is used in centrifuge machines, which allows the components of a sample to be separated and collected for further examination or testing.

What is centrifuge balancing?

A centrifuge needs to be balanced and needs also to be aligned correctly in order to spin smoothly and uniformly. If a centrifuge is not balanced correctly, it may vibrate or tremble, causing equipment damage and producing false or unreliable results. The weights and arrangement of the samples in the centrifuge tubes must be evenly distributed to balance a centrifuge. The tubes must also be appropriately positioned in the centrifuge rotor for a uniform balance.

Before usage, the rotor should be thoroughly inspected for any damage or deformities that may disturb its balance, and any necessary repairs should be done to avoid any error in the experiment. Failure to properly balance the equipment can lead to major issues.

Significance of balancing centrifuge

A centrifuge spins at thousands of revolutions per minute, so even minor weight imbalances surrounding the rotor get magnified and may lead the instrument to vibrate or shake. This has an effect on its performance and reliability, as well as shortening lifespan of machine and, in the worst-case scenario, causing a centrifuge explosion that might harm lab staff.

Why it is important to do centrifuge balancing?

- It is essential to balance a centrifuge since an imbalanced centrifuge can cause difficulties during the separation process and may also result in inaccurate or unreliable results i.e. insufficient separation of the sample components or in the components being mixed together again after separation.

- When a centrifuge is not properly balanced, it may vibrate or shake, causing damage to the equipment.

- Aside from these issues, an imbalanced centrifuge can be dangerous to operate. If the centrifuge is not properly balanced, the high speeds at which it spins might cause it to become unstable, resulting in accidents or injuries.

How to balance a centrifuge machine?

Portable benchtop

When using portable benchtop equipment, make sure the centrifuge is set on a firm, level surface. The rotor must then be loaded with tubes so that the center of gravity stays in the center of the rotor.

Fixed angle rotor devices

When loading a centrifuge with a fixed-angle rotor, consider your tubes in pairs and place them across from one another. It should be noted that the two tubes opposite one another should have the same mass, which requires that they must be filled with identical sample volumes.

If your tube count is odd, place one “balance tube” opposite your “single sample tube.” Please keep in mind that when filling the balance tube with water, it does not have to have the same amount of liquid as the sample tube on the other side of the rotor, but it must have the same mass. By evenly arranging the tubes around the rotor, a fixed-angle rotor centrifuge with an odd number of tubes can also be balanced.

Centrifuge with swinging bucket rotors

To load a centrifuge with a swinging bucket rotor, all rotor positions must be equipped with buckets, even if they are empty. Using the instrument without buckets may cause rotor damage. Furthermore, you have to make sure that the buckets can be quickly removed.

While loading tubes into buckets, make sure that adjacent buckets are loaded equally to avoid an imbalance across the center of rotation. Each bucket must also be balanced along its pivot axis. Use “balance tubes” if your sample tube number does not meet one of these parameters.

Balancing multiple-tubes centrifuge

Balancing three-tubes centrifuge

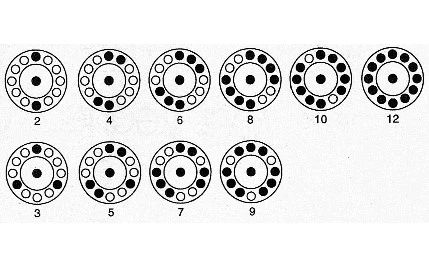

There are two ways to balance three pipes. The first method involves placing three sample tubes alongside three equalization tubes. Alternatively, the sample tubes could be spread uniformly around the rotor.

Balancing five-tubes centrifuge

Make a balancing tube and place two sets of three tubes in opposition to balance five tubes.

Balancing seven-tubes centrifuge

Use a balancing tube and oppose two sets of four tubes to balance seven tubes.

Keynotes for centrifuge balancing

Balance samples by mass instead of volume

- If all of the samples have the same density, their mass and volume will not match. In this case, it is easy to directly fill tubes. Yet weighing tubes is a good idea for safety.

- If the density of one substance differs somewhat from that of another, mass rather than volume must be examined. At last, the idea of equilibrium under consideration here is wholly dependent on mass.

- When it comes to volume, manufacturers will typically specify how full a tube can be. A good example would be to use no more than two-thirds of its available capacity.

Choose the appropriate size tubes for your centrifuge

Different centrifuges require different sizes of tubes. Larger centrifuges, in general, require larger microtubes. Using the incorrect size tube in a centrifuge might end up in a messy spill or damage to the centrifuge or the tube containing your sample.

Consult a more experienced laboratory technician if you’re unsure which tube size should be used for which size of centrifuge. Alternatively, review the manufacturer’s manual for the centrifuge you’re using. Most desktop mini centrifuges are used for 1.5 mL or 0.5 mL microtube.

Buckets must not be left out

If you have a centrifuge that has many buckets, and you may only require one or two of them for your laboratory samples. It could be easy to leave your opposing buckets empty on the ground. However, this is not a smart idea because running without buckets could cause rotor damage or catastrophic failure. Keep this in mind when assembling and balancing scientific equipment.

When “dummy tubes” are required, use them

There will always be cases where the number of samples to be centrifuged does not provide a balanced load. “Dummy” tubes could be used in this case. These can be filled with water or another liquid, but their density should be equal to your samples. Tubes should, however, be weighed rather than measured by volume.

Load your tubes in a symmetrical manner

Loading tubes symmetrically seems simple in theory, but it can be difficult for some to understand, especially when balancing many buckets, particularly those that pivot. The centrifuges with no buckets and a small number of gaps are the easiest to balance.

Consider an Imbalance Sensor Unit

Even if you believe you have loaded your samples correctly, there is always the possibility of human error. In this case, a device with an integrated imbalance sensor is useful. If an imbalance is detected, the device will quickly shut down.

Figure 2: figure represents positions of tubes for a balanced centrifuge (Haidar 2015)

How to check balancing of a centrifuge?

Inspect rotor

Examine the rotor for any damage or defects that can affect its balance. Inspect the rotor for cracks, dents, or other flaws that could cause it to spin irregularly.

Use balancing device

Some centrifuges include a built-in balancing system that help to make sure that the rotor is appropriately balanced. To use this device, follow the manufacturer’s instructions.

Evenly distribute the weights

Check that the weights and samples in the tubes are distributed uniformly in the rotor. This will aid in the centrifuge’s balance and lessen the possibility of vibration or trembling.

Spin the centrifuge at low speeds

Spin the centrifuge at low speeds and look for indicators of imbalance, like vibration or shaking, on the rotor. If the rotor looks to be spinning smoothly and evenly, increase the centrifuge speed to the appropriate level.

What should we do if centrifuge is not balanced?

Unbalanced centrifuges can vibrate greatly, potentially damaging the apparatus and causing a safety danger. If you feel that your centrifuge is not balanced, follow these steps:

Stop the centrifuge quickly

If you observe that the centrifuge is vibrating immensely, you must stop it immediately to avoid further damage.

Examine the machine and its surroundings

Check that the machine is appropriately levelled and that the environment is vibration-free.

Examine the rotor and samples

Ensure that the rotor is properly positioned in the machine and that the samples are placed evenly in the tubes or buckets.

Examine for any obvious problem

Examine the machine for any evident problems, such as an unbalanced load, a damaged rotor, or parts of machine that might be broken.

Contact with the manufacturer

If you are not able to figure out and resolve the issue, you should seek further assistance from the manufacturer. They may be capable of to provide more troubleshooting advice or recommend necessary repairs.

Conclusion

Centrifuge balance is a vital component in maintaining the safety, accuracy, and stability of centrifuge processes. Properly balanced centrifuges help in success of experiments and processes in scientific research, medical diagnostics, and industrial applications. Neglecting this essential factor might have devastating effects, such as equipment damage and inaccurate results.

References

- Castroagudin MR, Zhai Y, Li Z, Marnell MG, Glavy JSJC. 2016. Cyto-3D-print to attach mitotic cells. 68(4): 1641-1645.

- Haidar AM. 2015. Comprehensive model and experimental validation of passive vibration suppression for supercritical rotary machines.

- https://www.wikihow.com/Balance-a-Centrifuge